Design to Dispatch: Our Acacia Board Production Flow

The Complete Journey: How Our Acacia Cutting Boards Are Designed, Built, and Shipped

Producing a world-class cutting board is not just about woodworking. It’s about innovation, sustainability, hygiene, and delivering a product that brings both functionality and style into kitchens worldwide. At YangJiang Stellar Kitchenware, each Acacia cutting board begins with intention—and travels a journey of care and craftsmanship from design to global delivery.

Let’s take a look behind the scenes.

1. Design with Purpose and Planet in Mind

Every Custom eco friendly food safe Acacia cutting board starts with a design brief. Our philosophy combines aesthetics, sustainability, and usability. Our designers ensure that:

The grain pattern complements engraving or laser etching

The size and weight fit modern kitchen spaces

The board includes features like juice grooves or dual-sided use

We prioritize environmentally-conscious design:

Designs favor low-waste production layouts

We incorporate shapes that minimize offcuts and allow multi-functionality

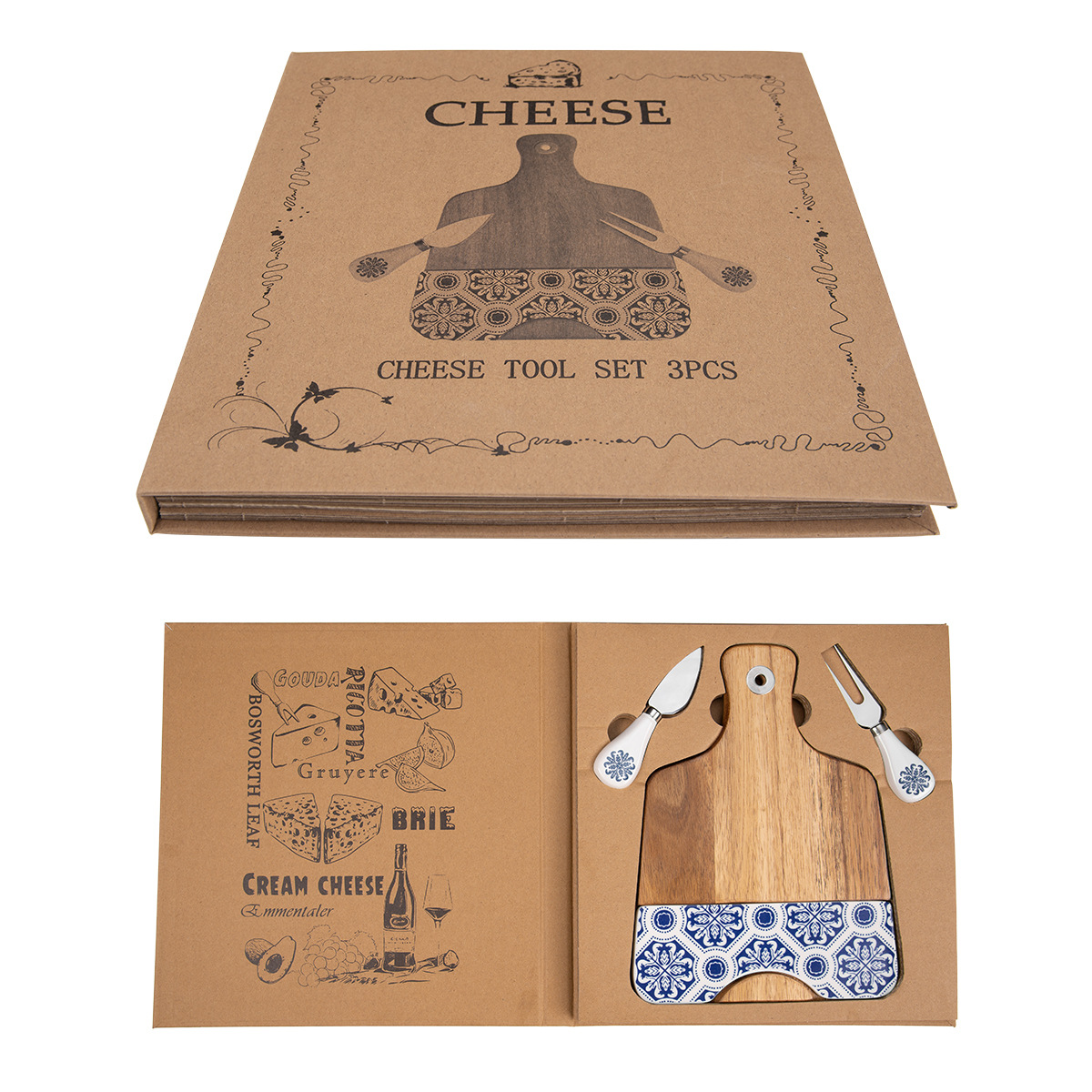

2. Integrating Functional Add-ons

What sets our products apart is thoughtful innovation.

For instance:

The Detachable food grade hybrid tray is engineered for multi-use, allowing easy separation of wet and dry ingredients

These trays are dishwasher tested and certified for food-grade safety

Meanwhile, the Non-toxic personalized engraved cutting board goes through an engraving step followed by a final antimicrobial seal—protecting the board from bacterial buildup while preserving the sharpness of personalized artwork.

These enhancements not only improve function but also elevate the board into a premium kitchen accessory.

.png)

3. Ethical Sourcing & Wood Preparation

We believe in responsibility from root to board.

All our Acacia is:

FSC-certified to guarantee responsible forestry

Selected for grain integrity and natural durability

Kiln-dried in-house to reduce moisture levels and prevent warping

This forms the basis of our Antibacterial Acacia board production, ensuring that every unit has consistent texture, density, and color.

Our ethical sourcing model also includes:

4. Finishing with Hygiene and Ease-of-Care

Finishing isn't an afterthought—it's a key to longevity and safety.

Each Custom food safe Acacia kitchen chopping board undergoes:

Triple-sealing with FDA-approved mineral oils

Machine polishing for smooth surfaces

Final buffing with food-safe wax for sheen and protection

The result is a Low maintenance antibacterial food grade Acacia cutting board that:

Resists odor absorption

Cleans easily without harboring bacteria

Stays beautiful after years of use

Our quality team inspects each unit for splinters, sanding irregularities, and oil absorption levels before packaging.

.png)

5. Smart Packaging and Global Logistics

After passing QC, the journey isn’t over—it’s just beginning.

We use:

Moisture-resistant packaging materials to protect during shipping

Eco-friendly padding for shock absorption

QR-coded inserts for care instructions and product authentication

Region-specific documentation accompanies each shipment to satisfy:

EU food-contact regulations

U.S. FDA labeling requirements

Asia-Pacific customs certifications

All boards are batch-logged for traceability from port to customer.

Whether headed to a boutique in Berlin or a retailer in Los Angeles, our boards arrive ready to impress.

Creating a cutting board is more than manufacturing—it’s a journey of values, craftsmanship, and vision. When you choose our Acacia wood boards, you choose a product built with thought, from forest to finish.

📧 Contact us: info@justwoodencuttingboard.com

📱 WhatsApp: +86 183 1248 3616

🏷️ Top 10 Chinese wood kitchenware Manufacturer: YangJiang Stellar Kitchenware

READ MORE:

Yangjiang Cuthaven Kitchenware Co.,Ltd

Yangjiang Cuthaven Kitchenware Co.,Ltd.

specializes in the production and export of high-quality metal and wooden kitchenware. With over 16 years of experience in the industry, we have established ourselves as a trusted partner for businesses worldwide.